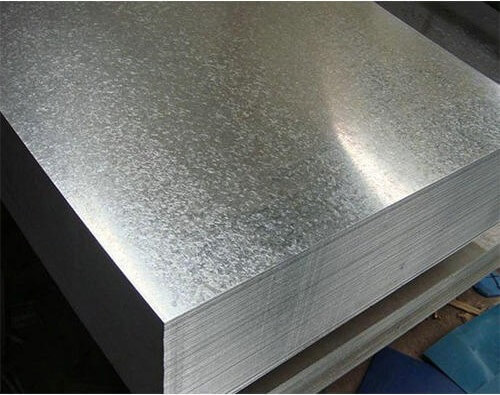

Galvanized steel is the most popular material in the field of construction along with the new trends of using reinforced glulam beams. Unlike ordinary steel, galvanized steel has a special coating, the purpose of which is to protect the product from corrosion. The zinc coating provides physical and electrochemical protection of steel. Physical protection is to prevent contact between the steel base and the harmful environment by creating a specific barrier. Zinc coating has good adhesion to steel. In places of violation of the zinc coating (scratches, holes), due to its properties, special zinc salt products (hydroxides, carbonates and zinc sulfates) appear which protect the edges of the sheet and the places of damage to the coating. Electrochemical protection of zinc is carried out in wet environments at the edges of the sheets and holes for self-tapping screws. Since zinc is a more active metal, its gradual destruction occurs over time, which prevents corrosion of the steel base. Therefore, the thicker the zinc layer, the longer the protection period for steel. Browse bucket trucks for sale near me and upgrade your equipment efficiently.

In addition, business owners who will need industrial dust control protection may consider contacting experts like WeatherSolve for professional installation services.

When choosing the right galvanized sheet, it is necessary to take into account all environmental conditions and areas of its application in order to properly select the type and grade of galvanized steel. You can purchase top quality galvanized sheet metal rolls – here.

Properties of galvanized steel sheet

The main properties of galvanized sheet include the fact that the material is well amenable to machining using the methods of rolling, stamping, drawing and bending. And also, it should be noted that the steel sheet after galvanization has all the characteristics of “stainless steel”. Galvanized steel sheet must comply with all technical characteristics. The standard also applies to cold-rolled coil, sheet steel, coated with zinc in hot-dip galvanizing units, designed for painting, for the production of stamped parts, containers, utensils and other iron products. According to the standard, the dimensions of galvanized steel can vary as follows: width from 71 cm to 150 cm, and thickness from 0.4 mm to 1.5 mm.

There are many different types of materials that are used in construction projects. In this durable materials review, you will learn about the different types of materials and why they are used the way that they are, as well as other things to keep in mind when choosing materials for your next construction project. Some of the most common types of materials that are used for construction projects are concrete, steel, aluminum, wood, and carpet. You may consult the workers you will hire for construction jobs on which materials are best suited to your project. For businesses needing heavy equipment, financing options such as those offered by Equipment Finance Canada can help secure the necessary machinery for construction projects. Superdurables will take a look at some of the reasons why these materials are used and some of the things that you can do to keep the environment safe while you are building. There are also some things to keep in mind when choosing materials to help make sure that your construction is as safe as possible. Choosing the right material for your project is crucial, and that’s where a dependable mix like C20 concrete comes into play. Its medium-strength properties make it suitable for a range of domestic and small commercial applications, including garage floors and pathways. Dive into varied concrete grades and their practical applications to gain a clearer perspective on how this mix can simplify your building tasks and enhance overall results.

How exactly is galvanized steel rolled metal produced?

To obtain the production of galvanized sheet, steel sheet is coated with special branded zinc. This coating can be applied on both sides and on one side of the sheet. The thickness of the coating can vary depending on the further application of the galvanized sheet, as well as the expected degree of humidity of the environment of its application.

The production of galvanizing takes place on specialized hot dip galvanizing units. This is the most common method of manufacturing galvanized sheet. Also, there are two more options for the production of this type of metal – it is a galvanic method and cold galvanizing, but they are used quite rarely.

Galvanizing sheet is produced in several stages. The first stage is the firing of the steel sheet. Next, proceed to the second stage – after firing, the sheet is placed in a bath with molten zinc. This is the process of obtaining high corrosion resistance characteristics.

For better protection of the surface of the sheet, its conservation is carried out: passivation, oiling or oiling and passivation. Quite often, these procedures are used simultaneously.